Industrial Safety & Risk Management Training Programs

Our expert-led training courses are designed to equip engineers, safety professionals, and operational staff with the practical knowledge and regulatory insight needed to manage risks and ensure compliance in high-hazard industries. All training is based on international best practices, real-world case studies, and current regulatory frameworks.

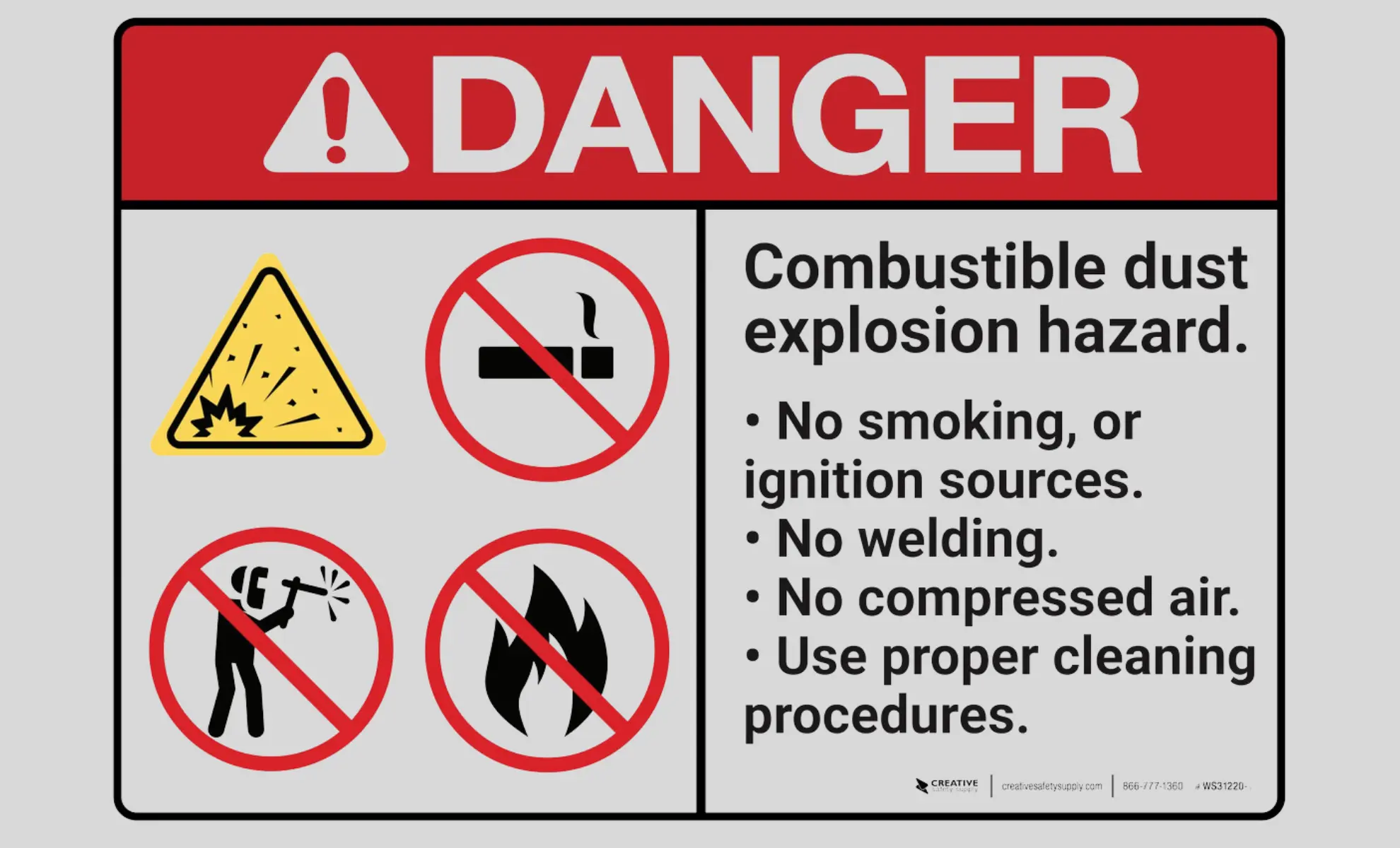

Combustible Dust Hazard Training

This hands-on course addresses the hidden but deadly risks of combustible dust, helping participants recognize conditions that could lead to dust explosions and fires.

What You’ll Learn:

- Dust hazard analysis (DHA) methodology

- NFPA standards (652, 654, 68) for dust safety compliance

- Primary vs secondary explosions and explosion pentagon principles

- Ventilation and housekeeping best practices

- Selecting dust-rated electrical equipment and mitigation systems

Applicable Industries: Food processing, pharmaceuticals, chemicals, and metalworking.

Major Hazard Regulations (MHR) Compliance Training

This course provides a comprehensive overview of major hazard facility regulations in South Africa, equipping teams to meet legal and regulatory obligations.

Training Includes:

- Legal framework and classification of major hazard facilities

- Safety Case or MHF License preparation

- Hazard identification and risk management expectations

- Regulatory engagement and audit readiness

- Emergency planning and community impact considerations

Standards & Guidelines Referenced: South African Regulations (Click Here to view the Full Regulations)

HAZOP (Hazard and Operability) Training

Our HAZOP training builds deep competence in facilitating and participating in effective hazard studies using international best practices.

Learning Outcomes:

- Understanding design intent and deviation principles

- Applying HAZOP guidewords to piping & instrumentation diagrams (P&IDs)

- Team roles, facilitator techniques, and software tools

- Integration with SIL determination and LOPA

- Hands-on HAZOP workshops using realistic case studies

Relevant Standards: IEC 61882, CCPS Guidelines

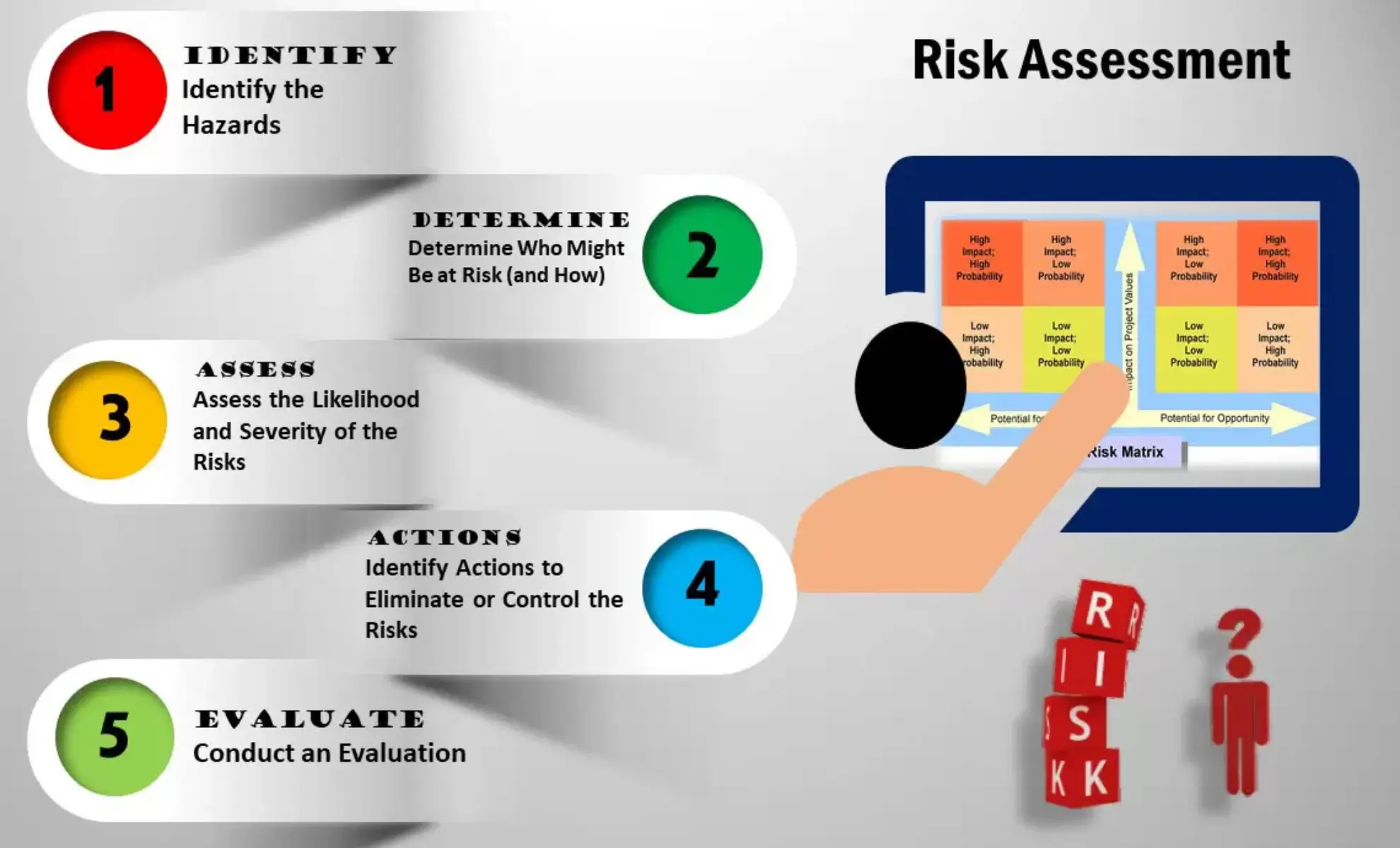

Quantitative Risk Assessment (QRA) Training

Our QRA training empowers engineers to conduct robust, defensible risk assessments for major accident hazards.

What You’ll Master:

- Hazard identification tools (HAZID, HAZOP)

- Frequency estimation using Fault tree analysis, historical data, and event trees

- Consequence modelling with Gexcon or equivalent tools

- Risk presentation: FN curves, individual risk contours

- ALARP demonstration and risk-reduction strategies

Industry Applications: Oil & gas, petrochemicals, pharmaceuticals, and energy

Hydrogen Safety Training

Hydrogen is a clean energy vector—but it carries unique risks. This course provides specialized training on hydrogen safety in industrial and energy applications.

Training Features:

- Hydrogen properties and dispersion behavior

- Fire and explosion hazards: BLEVE, VCE, jet fires

- Design for safety: ventilation, leak detection, and passive fire protection

- Hazardous area classification and equipment selection for hydrogen

- Compliance with ISO/TR 15916, IEC 60079, and local hydrogen codes

Suitable For: Renewable energy engineers, chemical plant designers, HSE officers

Emergency Response Planning Compliance

Course Overview:

This practical and essential training course equips organizations with the knowledge and tools to develop and implement Emergency Response Plans in accordance with SANS 1514. This South African National Standard outlines the minimum requirements for preparing, executing, and maintaining effective emergency response procedures to safeguard life, property, and the environment during crises such as fire, chemical spills, or natural disasters.

Who Should Attend:

- Health and Safety Officers

- Emergency response coordinators

- Facility and operations managers

- Risk managers and EHS professionals

- Compliance and regulatory officers

What You’ll Learn:

- Understanding the framework and purpose of SANS 1514

- Key elements of an effective emergency response plan (ERP)

- Legal and regulatory obligations under South African law

- Roles and responsibilities of response personnel

- Communication strategies during emergencies

- Coordination with external emergency services

- Testing, training, and continuous improvement of ERPs

Benefits:

- Achieve compliance with national emergency preparedness standards

- Reduce downtime, injuries, and environmental impact during incidents

- Improve organizational readiness and resilience

- Build a culture of safety and proactive risk management

- Protect assets, reputation, and legal standing

Delivery Options

- On-site at your facility (customized to your operations)

- Virtual instructor-led training (VILT)

- Hybrid training with practical simulations and workshops

Ignition Source Control Training

This training focuses on identifying, managing, and mitigating ignition sources in industrial environments, particularly where flammable gases, vapors, or dust are present.

Key Topics Covered:

- Types of ignition sources: electrical, mechanical, electrostatic, lightning

- Intrinsically safe equipment and ATEX compliance

- Hot work permits and ignition source risk assessments

- Ignition probability factors in Quantitative Risk Assessments (QRA) and Hazardous Area Classification (HAC) studies

- Ignition source control within hazardous area classifications

Ideal For: Process engineers, maintenance personnel, and safety managers working in explosive atmospheres.

Process Safety Training

Overview

Our Process Safety Training is designed for engineers, operations personnel, and safety professionals who manage or operate hazardous processes. Rooted in international best practices, this course empowers participants with the tools, methodologies, and mindset necessary to prevent major accidents, protect assets, and uphold compliance.

Course Objectives

- Understand the principles of process safety and how they differ from occupational safety.

- Gain knowledge of hazard identification and risk assessment methods (HAZOP, LOPA, FMEA).

- Learn to apply barrier models, bowtie analysis, and safety integrity level (SIL) concepts.

- Enhance understanding of process safety culture and performance indicators.

Topics Covered

- The Four Pillars of Risk-Based Process Safety (CCPS)

- Process Hazard Analysis (PHA) using HAZOP (IChemE Guidelines)

- Layers of Protection Analysis (LOPA)

- Management of Change (MOC)

- Incident Investigation and Root Cause Analysis

- Mechanical Integrity and Inspection Planning

- Human Factors and Organizational Controls

- Safety Case and COMAH/Seveso III compliance (EU alignment)

- International Codes: API, OSHA 1910.119 (PSM), IEC 61511 (SIS), ISO 45001

Who Should Attend?

- Process and Chemical Engineers

- Safety, Health & Environment (SHE) Officers

- Project Managers

- Maintenance and Operations Staff

- Compliance and Regulatory Officers

Standards & References

- CCPS (AIChE) – Guidelines for Risk Based Process Safety

- IChemE – HAZOP & Hazard Study Training Manuals

- AIChE – Center for Chemical Process Safety Training Materials

- IEC 61511 / ISA S84 – Functional Safety for the Process Industry

- OSHA 29 CFR 1910.119 – Process Safety Management Standard

Why Train With Us?

- Courses developed and delivered by Certified Process Safety Professionals (CCPSC) and Chartered Chemical Engineers (CEng MIChemE)

- Case-based learning with real industrial examples

- Aligned with global benchmarks to support ISO, OSHA, and SEVESO III compliance

- Certificates of Competence and CPD accreditation provided

Combustible Dust Hazard Awareness & Management Training

Overview

Combustible dust poses a serious fire and explosion hazard in many industrial settings, including food processing, wood handling, chemical manufacturing, metalwork, and plastics. Our Combustible Dust Training program provides comprehensive insight into the science, risks, and control of dust explosions in compliance with international standards and regulations.

Course Objectives

- Understand the fundamentals of combustible dust, deflagration, and explosion dynamics.

- Identify operations that generate explosive dust clouds and layered deposits.

- Learn how to evaluate dust explosibility (Kst, Pmax, MEC, MIE).

- Gain skills in hazard recognition, risk assessment, and practical mitigation strategies.

- Ensure compliance with major international codes, including NFPA 652, ATEX 137, and OSHA 1910.

Topics Covered

Fundamentals of Combustible Dust

- What is a combustible dust? – Definitions and properties

- Dust Explosion Pentagon vs Fire Triangle

- Common industries at risk (grain, pharmaceuticals, rubber, textiles, etc.)

Testing & Classification

- Kst and Pmax values (dust explosion severity)

- Minimum Ignition Energy (MIE), Minimum Explosible Concentration (MEC)

- Dust sample collection and laboratory testing (per ASTM E1226, EN 14034)

Hazard Identification & Risk Assessment

- Dust Hazard Analysis (DHA) as per NFPA 652

- Secondary explosions and fugitive dust

- Hot work, static discharge, and ignition sources

- Area classification and zoning (ATEX 1999/92/EC – Zone 20, 21, 22)

Engineering and Administrative Controls

- Housekeeping and dust control systems

- Explosion venting, suppression, and isolation (per NFPA 68, NFPA 69)

- Inerting and spark detection systems

- Duct design and dust collector safety

Regulatory Framework & Compliance

- NFPA 652, NFPA 654, NFPA 484, NFPA 61 (Industry-specific)

- OSHA 1910 Subpart Z and Combustible Dust NEP

- ATEX Directives 2014/34/EU and 1999/92/EC (EU compliance)

- CCPS Guidelines for Dust Explosion Prevention & Mitigation

Case Studies & Incident Review

- Imperial Sugar explosion (USA)

- Grain silo disasters

- Lessons learned: Root causes and failures of risk control measures

Who Should Attend?

- Plant Managers and Operators

- EHS and Process Safety Professionals

- Maintenance Supervisors

- Facility Engineers

- Auditors and Compliance Officers

- Insurance and Risk Consultants

Training Methodology

- Interactive workshops and quizzes

- Videos of explosion demonstrations

- Group DHA exercises and facility walkthrough simulations

- Optional site-specific assessments and dust audits (upon request)

Global Standards Referenced

- NFPA 652: Standard on the Fundamentals of Combustible Dust

- CCPS (AIChE): Guidelines for Combustible Dust Hazard Management

- IChemE Safety Centre Resources

- ATEX 137 Directive (Directive 1999/92/EC)

- OSHA Combustible Dust NEP

- ISO 80079-20-2: Explosive atmospheres – properties of substances

Training Outcomes

Participants will:

- Be able to conduct a basic Dust Hazard Analysis (DHA)

- Understand how to classify and mitigate dust explosion risks

- Gain confidence in aligning operations with international regulatory requirements

- Receive a Certificate of Competency upon completion